Discover sustainable practices in pharmaceutical manufacturing and their impact on the environment and society. Create a healthier future for all.

Exploring Sustainable Practices in Pharmaceutical Manufacturing

Table of Contents

- Introduction

- The Importance of Sustainable Practices in Pharmaceutical Manufacturing

- Innovative Technologies for Sustainable Pharmaceutical Production

- Sustainable Packaging Solutions for Pharmaceutical Products

- Collaborating with Suppliers for Sustainable Raw Materials in Pharmaceutical Manufacturing

- Q&A

- Conclusion

“Empowering the future of medicine through sustainable manufacturing practices.”

Introduction

Pharmaceutical manufacturing is a crucial industry that plays a significant role in providing essential medicines to people around the world. However, the production of pharmaceuticals can have a significant impact on the environment and contribute to global issues such as pollution and climate change. As a result, there has been a growing focus on exploring sustainable practices in pharmaceutical manufacturing to reduce its environmental footprint and promote more responsible production methods. In this article, we will delve into the concept of sustainable practices in pharmaceutical manufacturing and discuss the potential benefits and challenges of implementing them.

The Importance of Sustainable Practices in Pharmaceutical Manufacturing

Pharmaceutical manufacturing is a vital industry that plays a crucial role in providing life-saving medications to people all over the world. However, with the increasing concern for environmental sustainability, the pharmaceutical industry is facing pressure to adopt more sustainable practices in their manufacturing processes. In this article, we will explore the importance of sustainable practices in pharmaceutical manufacturing and how it can benefit both the industry and the environment.

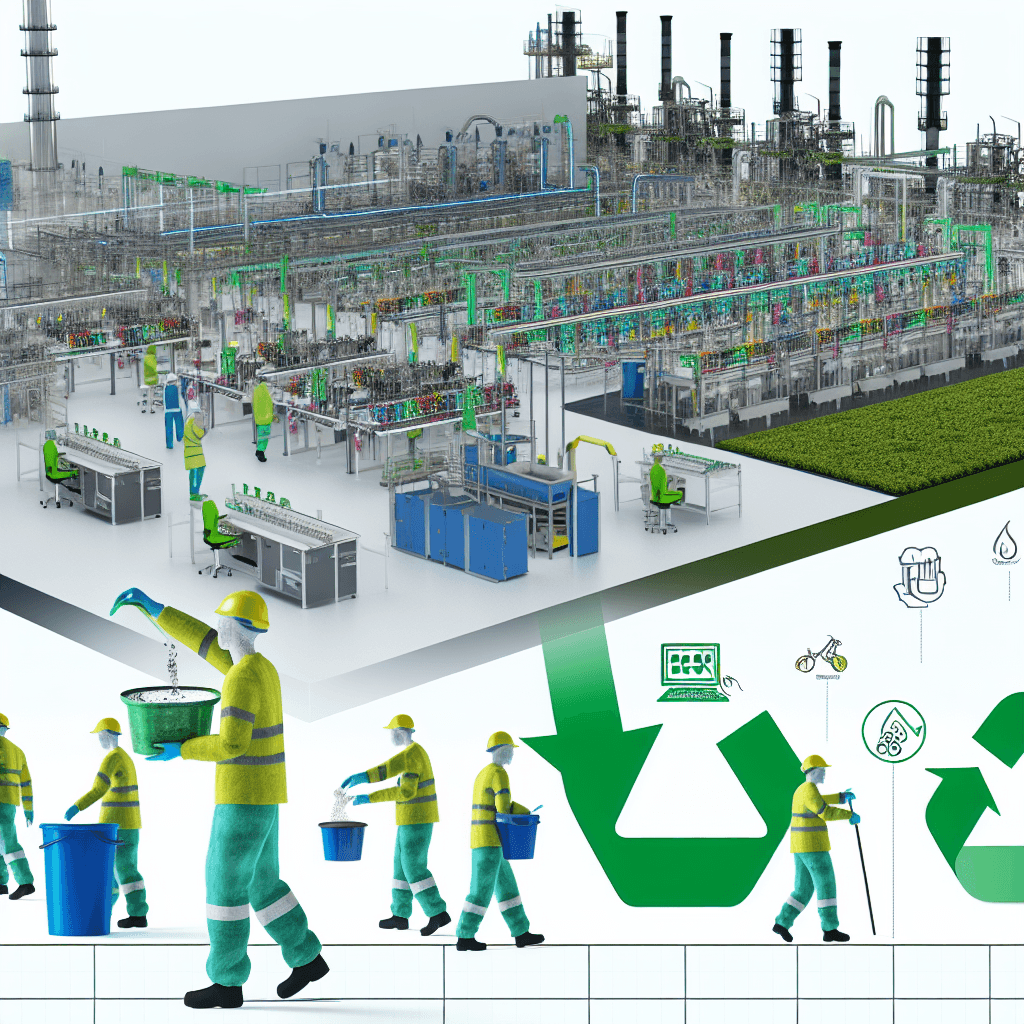

The pharmaceutical industry is known for its complex and resource-intensive manufacturing processes. From sourcing raw materials to packaging and distribution, every step in the production of medications has a significant impact on the environment. The use of fossil fuels, water, and other natural resources, as well as the generation of waste and emissions, are all part of the pharmaceutical manufacturing process. As a result, the industry has been under scrutiny for its contribution to environmental degradation.

One of the main reasons why sustainable practices are crucial in pharmaceutical manufacturing is the industry’s significant carbon footprint. According to a report by the International Federation of Pharmaceutical Manufacturers and Associations (IFPMA), the pharmaceutical industry is responsible for approximately 5% of global carbon emissions. This is a significant contribution to climate change, and it is essential for the industry to take action to reduce its impact.

Moreover, the use of non-renewable resources in pharmaceutical manufacturing is also a cause for concern. The production of medications requires a vast amount of energy, which is primarily derived from fossil fuels. As these resources are finite, their depletion will have a severe impact on the industry’s ability to produce medications in the future. Therefore, it is crucial for pharmaceutical companies to adopt sustainable practices that reduce their reliance on non-renewable resources.

Aside from the environmental impact, sustainable practices in pharmaceutical manufacturing can also bring economic benefits to the industry. By implementing energy-efficient processes and reducing waste, pharmaceutical companies can save on production costs. This, in turn, can lead to more affordable medications for consumers. Additionally, sustainable practices can also improve the industry’s reputation and attract environmentally-conscious consumers, which can lead to increased sales and profits.

Furthermore, the adoption of sustainable practices in pharmaceutical manufacturing can also have a positive impact on public health. The production of medications often involves the use of hazardous chemicals, which can pose a risk to both the environment and human health. By implementing sustainable practices, such as using green chemistry principles and reducing the use of harmful chemicals, the industry can minimize its impact on public health.

In recent years, there has been a growing demand for sustainable medications from consumers. This has led to an increase in the number of pharmaceutical companies that are incorporating sustainable practices into their manufacturing processes. For instance, some companies have started using renewable energy sources, such as solar and wind power, to reduce their carbon footprint. Others have implemented closed-loop systems to recycle and reuse materials, reducing waste and conserving resources.

In conclusion, the importance of sustainable practices in pharmaceutical manufacturing cannot be overstated. The industry’s significant carbon footprint, reliance on non-renewable resources, and potential impact on public health make it crucial for pharmaceutical companies to adopt sustainable practices. By doing so, the industry can reduce its environmental impact, save on production costs, and improve its reputation. As consumers become more environmentally-conscious, the demand for sustainable medications will continue to grow, making it imperative for the pharmaceutical industry to prioritize sustainability in its manufacturing processes.

Innovative Technologies for Sustainable Pharmaceutical Production

The pharmaceutical industry plays a crucial role in providing life-saving medications to people around the world. However, the production of these medications can have a significant impact on the environment. As the demand for pharmaceuticals continues to rise, it is essential for the industry to adopt sustainable practices to minimize its environmental footprint. In recent years, there has been a growing focus on developing innovative technologies for sustainable pharmaceutical production.

One of the key areas of focus in sustainable pharmaceutical production is reducing energy consumption. Traditional pharmaceutical manufacturing processes require large amounts of energy, which contributes to greenhouse gas emissions and increases the industry’s carbon footprint. To address this issue, pharmaceutical companies are turning to innovative technologies such as continuous manufacturing and process intensification.

Continuous manufacturing involves the continuous flow of raw materials through the production process, as opposed to the traditional batch processing method. This technology not only reduces energy consumption but also minimizes waste and improves product quality. Additionally, process intensification involves optimizing the production process to reduce the amount of energy and resources required. This can be achieved through the use of advanced process control systems and the integration of renewable energy sources.

Another area of focus in sustainable pharmaceutical production is the reduction of water usage. The production of pharmaceuticals requires large amounts of water for various processes, such as cleaning and cooling. However, with the increasing scarcity of water resources, it is crucial for the industry to find ways to reduce its water consumption. One innovative technology that has been developed for this purpose is the use of closed-loop water systems. These systems recycle and reuse water, reducing the need for fresh water and minimizing wastewater discharge.

In addition to reducing energy and water consumption, sustainable pharmaceutical production also involves minimizing waste generation. Traditional pharmaceutical manufacturing processes can produce significant amounts of waste, including hazardous materials. To address this issue, companies are turning to green chemistry and biocatalysis. Green chemistry involves using environmentally friendly processes and materials, while biocatalysis utilizes enzymes and microorganisms to produce pharmaceuticals. These technologies not only reduce waste but also have the potential to improve the efficiency and cost-effectiveness of the production process.

Furthermore, the use of renewable energy sources is gaining traction in the pharmaceutical industry. Solar, wind, and geothermal energy are being explored as alternatives to traditional fossil fuels. These renewable energy sources not only reduce the industry’s carbon footprint but also provide a more sustainable and cost-effective energy solution. Additionally, the use of renewable energy can help pharmaceutical companies meet their sustainability goals and improve their public image.

Another innovative technology that is being developed for sustainable pharmaceutical production is 3D printing. This technology allows for the precise and customizable production of medications, reducing the need for excess materials and minimizing waste. 3D printing also has the potential to improve drug delivery systems, making medications more effective and reducing the amount of medication needed for treatment.

In conclusion, the pharmaceutical industry is making significant strides towards sustainable production through the adoption of innovative technologies. These technologies not only reduce the industry’s environmental impact but also have the potential to improve efficiency and reduce costs. As the demand for pharmaceuticals continues to grow, it is crucial for the industry to continue exploring and implementing sustainable practices to ensure a healthier and more sustainable future for all.

Sustainable Packaging Solutions for Pharmaceutical Products

The pharmaceutical industry plays a crucial role in providing essential medicines to people all over the world. However, with the increasing concern for environmental sustainability, the industry is facing pressure to adopt more sustainable practices in all aspects of its operations. One area that has gained significant attention is the packaging of pharmaceutical products. In this section, we will explore the importance of sustainable packaging solutions in pharmaceutical manufacturing and the various options available.

The packaging of pharmaceutical products serves multiple purposes, including protecting the product from damage, ensuring its safety and efficacy, and providing information to the consumer. However, traditional packaging materials such as plastic and aluminum have a significant impact on the environment. These materials are non-biodegradable and can take hundreds of years to decompose, contributing to the growing problem of plastic pollution. As a result, pharmaceutical companies are now looking for more sustainable alternatives to reduce their environmental footprint.

One of the most promising sustainable packaging solutions for pharmaceutical products is the use of biodegradable materials. These materials are derived from renewable sources such as plants and can decompose naturally, reducing the amount of waste in landfills. Biodegradable packaging is also recyclable, making it a more environmentally friendly option. Some examples of biodegradable materials used in pharmaceutical packaging include corn starch, bamboo, and paper.

Another sustainable packaging solution gaining popularity in the pharmaceutical industry is the use of recycled materials. This involves using materials that have already been used and processed, reducing the need for new resources. Recycled materials can be used to make packaging for various pharmaceutical products, including bottles, boxes, and blister packs. This not only reduces the environmental impact but also helps to conserve natural resources.

In addition to the materials used, the design of the packaging also plays a crucial role in its sustainability. Packaging that is designed to be compact and lightweight can reduce the amount of material used, resulting in less waste. This is especially important for pharmaceutical products that are shipped globally, as it can significantly reduce the carbon footprint of transportation. Furthermore, innovative designs such as refillable or reusable packaging can also contribute to sustainability by reducing the need for new packaging for each product.

Apart from the materials and design, the disposal of pharmaceutical packaging also needs to be considered for sustainable practices. Many pharmaceutical products come with specific disposal instructions, and it is essential for consumers to follow them to ensure proper disposal. For example, some packaging may be labeled as compostable, and it is crucial to dispose of it in a compost bin rather than a regular trash can. This not only reduces waste but also prevents harmful chemicals from leaching into the environment.

In conclusion, sustainable packaging solutions are crucial for the pharmaceutical industry to reduce its environmental impact. Biodegradable and recycled materials, as well as innovative designs, are some of the options available for sustainable packaging. However, it is also essential for consumers to play their part by following proper disposal instructions. As the demand for sustainable practices continues to grow, it is crucial for pharmaceutical companies to prioritize sustainability in their packaging choices to ensure a healthier planet for future generations.

Collaborating with Suppliers for Sustainable Raw Materials in Pharmaceutical Manufacturing

Pharmaceutical manufacturing is a complex and highly regulated industry that plays a crucial role in providing life-saving medications to people around the world. However, the production of these medications can have a significant impact on the environment, making it essential for pharmaceutical companies to adopt sustainable practices. One crucial aspect of sustainable pharmaceutical manufacturing is collaborating with suppliers to ensure the use of sustainable raw materials.

The use of sustainable raw materials in pharmaceutical manufacturing is vital for several reasons. Firstly, it reduces the environmental impact of the production process. Many raw materials used in pharmaceuticals are derived from natural resources, such as plants and minerals. The extraction and processing of these resources can have a significant impact on the environment, including deforestation, water pollution, and greenhouse gas emissions. By using sustainable raw materials, pharmaceutical companies can minimize their environmental footprint and contribute to a healthier planet.

Secondly, the use of sustainable raw materials can also have a positive impact on the health and well-being of individuals. Many pharmaceutical products are made from natural resources that are becoming scarce due to overexploitation. By using sustainable raw materials, pharmaceutical companies can help preserve these resources for future generations and ensure the availability of essential medications.

Collaborating with suppliers is crucial for pharmaceutical companies to ensure the use of sustainable raw materials. Suppliers play a significant role in the pharmaceutical supply chain, providing the necessary ingredients and materials for the production of medications. Therefore, it is essential for pharmaceutical companies to work closely with their suppliers to ensure the sustainability of their raw materials.

One way pharmaceutical companies can collaborate with suppliers for sustainable raw materials is by setting clear sustainability standards and expectations. These standards should cover all aspects of the supply chain, from sourcing to production and transportation. By clearly communicating their sustainability requirements, pharmaceutical companies can ensure that their suppliers understand the importance of using sustainable raw materials and are committed to meeting these standards.

Another crucial aspect of collaborating with suppliers for sustainable raw materials is conducting regular audits and assessments. Pharmaceutical companies should regularly review their suppliers’ practices to ensure they are meeting the sustainability standards set forth. These audits can help identify any areas of improvement and provide an opportunity for suppliers to make necessary changes to their processes.

In addition to setting standards and conducting audits, pharmaceutical companies can also collaborate with suppliers by providing support and resources. This can include training programs on sustainable practices, sharing best practices, and providing financial incentives for suppliers who meet or exceed sustainability standards. By working together, pharmaceutical companies and their suppliers can create a more sustainable supply chain and contribute to a healthier planet.

Furthermore, collaboration with suppliers can also lead to innovation and the development of new, sustainable raw materials. By working closely with suppliers, pharmaceutical companies can encourage the use of alternative, more sustainable materials in the production of medications. This can lead to the development of new processes and technologies that are more environmentally friendly and can help reduce the industry’s overall environmental impact.

In conclusion, collaborating with suppliers for sustainable raw materials is a crucial aspect of sustainable pharmaceutical manufacturing. By setting clear standards, conducting regular audits, and providing support and resources, pharmaceutical companies can ensure the use of sustainable raw materials in their production processes. This not only benefits the environment but also contributes to the availability of essential medications and the well-being of individuals. By working together, pharmaceutical companies and their suppliers can create a more sustainable future for the industry and the planet.

Q&A

1. What are some sustainable practices in pharmaceutical manufacturing?

Some sustainable practices in pharmaceutical manufacturing include reducing energy and water consumption, implementing waste management and recycling programs, using renewable energy sources, and promoting sustainable sourcing of raw materials.

2. How can pharmaceutical companies reduce their environmental impact?

Pharmaceutical companies can reduce their environmental impact by implementing sustainable practices such as reducing energy and water consumption, using renewable energy sources, promoting sustainable sourcing of raw materials, and implementing waste management and recycling programs.

3. Why is it important for the pharmaceutical industry to adopt sustainable practices?

It is important for the pharmaceutical industry to adopt sustainable practices because it can help reduce their environmental impact, improve their public image, and potentially save costs in the long run. Additionally, as a highly regulated industry, implementing sustainable practices can also help companies comply with environmental regulations.

4. Are there any challenges in implementing sustainable practices in pharmaceutical manufacturing?

Yes, there can be challenges in implementing sustainable practices in pharmaceutical manufacturing. Some of these challenges include high initial costs, lack of awareness or understanding of sustainable practices, and potential resistance to change from traditional methods. Additionally, the complex and highly regulated nature of the pharmaceutical industry can also pose challenges in implementing sustainable practices.

Conclusion

In conclusion, exploring sustainable practices in pharmaceutical manufacturing is crucial for the industry to reduce its environmental impact and promote long-term sustainability. By implementing sustainable practices such as reducing energy and water consumption, using renewable resources, and properly managing waste, pharmaceutical companies can not only reduce their carbon footprint but also improve their reputation and contribute to a healthier planet. It is important for the industry to continue researching and implementing sustainable solutions in order to ensure a more sustainable future for both the pharmaceutical industry and the environment.