Discover how research is transforming the way healthcare equipment is designed, leading to more efficient and effective medical devices.

How Research is Revolutionizing Healthcare Equipment Design

Table of Contents

- Introduction

- Advancements in 3D Printing Technology for Customized Medical Devices

- The Impact of Artificial Intelligence on Medical Equipment Design and Functionality

- Innovative Materials and Their Role in Improving Durability and Performance of Healthcare Equipment

- The Role of User-Centered Design in Creating More User-Friendly and Accessible Medical Devices

- Q&A

- Conclusion

“Transforming healthcare, one innovative design at a time through cutting-edge research.”

Introduction

Research plays a crucial role in revolutionizing healthcare equipment design. With advancements in technology and a growing understanding of human anatomy and physiology, researchers are constantly pushing the boundaries of what is possible in terms of medical equipment design. This has led to the development of innovative and more efficient tools and devices that are transforming the way healthcare is delivered. In this introduction, we will explore how research is driving the evolution of healthcare equipment design and the impact it is having on patient care.

Advancements in 3D Printing Technology for Customized Medical Devices

The field of healthcare equipment design has undergone a significant transformation in recent years, thanks to advancements in 3D printing technology. This revolutionary technology has allowed for the creation of customized medical devices that are tailored to the specific needs of individual patients. This has not only improved the overall quality of healthcare but has also reduced costs and increased efficiency in the production of medical equipment.

One of the key benefits of 3D printing technology in healthcare equipment design is the ability to create personalized medical devices. Traditional manufacturing methods often involve mass production of standardized devices, which may not be suitable for every patient. With 3D printing, medical devices can be designed and produced based on the unique anatomical features of each patient. This has been particularly beneficial in the field of orthopedics, where customized implants and prosthetics can be created to fit the exact specifications of a patient’s body.

Moreover, 3D printing technology has also allowed for the creation of complex and intricate designs that were previously impossible to achieve with traditional manufacturing methods. This has opened up new possibilities for the design of medical devices, such as intricate surgical tools and implants with complex internal structures. These designs not only improve the functionality of the devices but also reduce their weight and size, making them more comfortable for patients to use.

Another significant advantage of 3D printing in healthcare equipment design is the speed and efficiency of production. Traditional manufacturing methods often involve multiple steps and processes, which can be time-consuming and costly. With 3D printing, a medical device can be designed and produced in a matter of hours, significantly reducing the time and cost involved in the production process. This has been particularly beneficial in emergency situations where a patient may require a customized medical device immediately.

Furthermore, 3D printing technology has also allowed for the production of medical devices using a wide range of materials. This has expanded the possibilities for healthcare equipment design, as different materials can be used to create devices with specific properties and functions. For example, 3D printing has enabled the production of biocompatible materials that can be used to create implants and prosthetics that are safe for use within the human body.

The use of 3D printing technology in healthcare equipment design has also led to a significant reduction in waste and environmental impact. Traditional manufacturing methods often involve the use of large quantities of materials, which can result in a significant amount of waste. With 3D printing, only the necessary amount of material is used, reducing waste and minimizing the environmental impact of production. This is particularly important in the healthcare industry, where sustainability and environmental responsibility are becoming increasingly important.

In addition to these benefits, 3D printing technology has also allowed for the creation of prototypes and models for testing and development purposes. This has been particularly useful in the design of complex medical devices, as it allows for multiple iterations and improvements before the final product is produced. This not only ensures the quality and functionality of the device but also reduces the risk of errors and malfunctions.

In conclusion, the advancements in 3D printing technology have revolutionized healthcare equipment design. The ability to create personalized, complex, and efficient medical devices has significantly improved the quality of healthcare and reduced costs. As this technology continues to evolve, we can expect to see even more innovative and life-changing medical devices being created, further improving the healthcare industry.

The Impact of Artificial Intelligence on Medical Equipment Design and Functionality

The field of healthcare equipment design has undergone a significant transformation in recent years, thanks to the advancements in artificial intelligence (AI) and its integration into medical devices. AI has revolutionized the way medical equipment is designed, manufactured, and used, leading to improved functionality, accuracy, and efficiency. This article will explore the impact of AI on medical equipment design and functionality, and how it is changing the landscape of healthcare.

One of the most significant contributions of AI to medical equipment design is its ability to analyze vast amounts of data and identify patterns that humans may not be able to detect. This has led to the development of more accurate and efficient diagnostic tools, such as AI-powered imaging systems. These systems use algorithms to analyze medical images and detect abnormalities, providing doctors with more accurate and timely diagnoses.

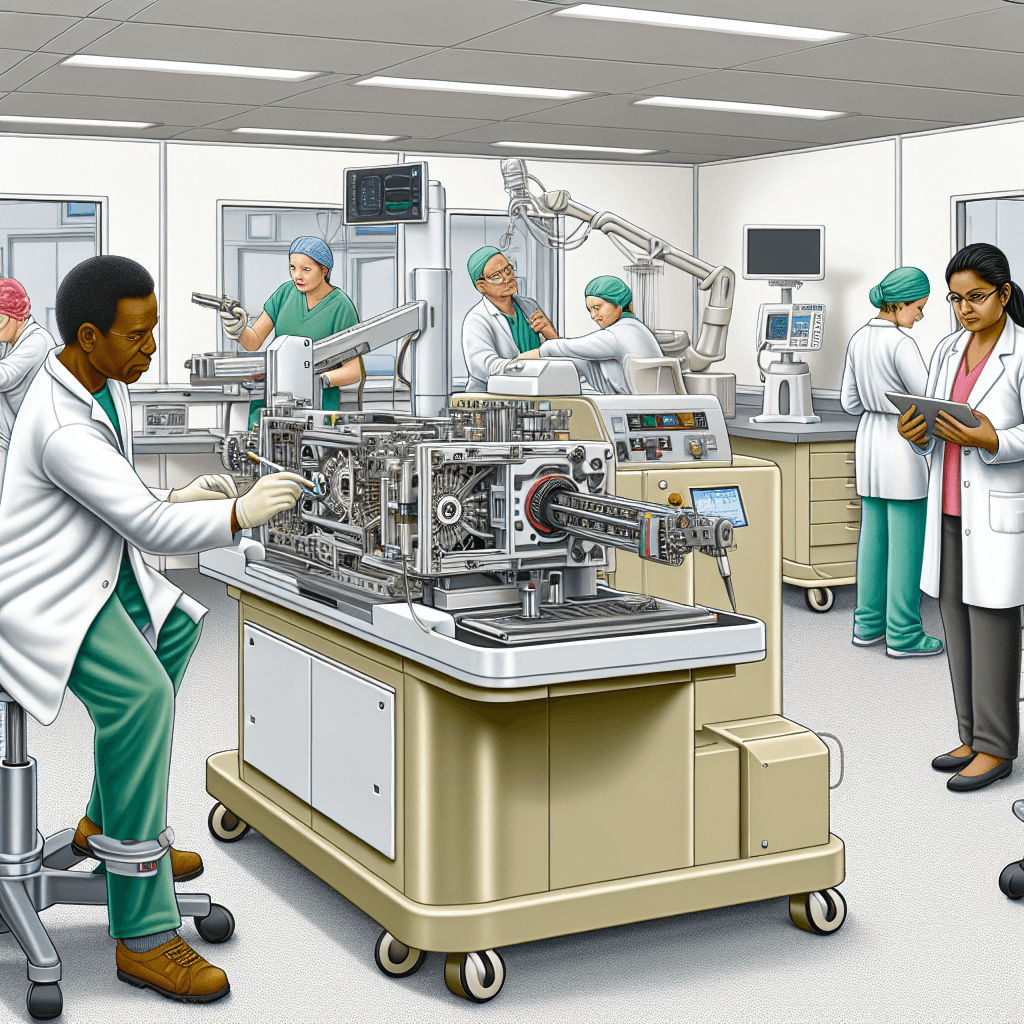

Moreover, AI has also played a crucial role in improving the functionality of medical equipment. For instance, AI-powered surgical robots have revolutionized the field of surgery by providing surgeons with enhanced precision, control, and dexterity. These robots can perform complex procedures with minimal invasiveness, reducing the risk of complications and improving patient outcomes.

In addition to improving accuracy and functionality, AI has also made medical equipment more user-friendly. With the integration of natural language processing (NLP) technology, medical devices can now understand and respond to voice commands, making them more accessible for healthcare professionals. This has significantly reduced the learning curve for using new medical equipment, allowing doctors and nurses to focus on patient care rather than device operation.

Another significant impact of AI on medical equipment design is its ability to continuously learn and adapt. This has led to the development of smart medical devices that can monitor patient health in real-time and adjust treatment accordingly. For instance, AI-powered insulin pumps can analyze a patient’s blood sugar levels and deliver the appropriate amount of insulin, reducing the risk of hypoglycemia or hyperglycemia.

Furthermore, AI has also enabled the development of predictive maintenance systems for medical equipment. These systems use machine learning algorithms to analyze data from medical devices and predict when maintenance or repairs may be needed. This not only reduces downtime but also ensures that medical equipment is always functioning at its optimal level, improving patient care and reducing costs for healthcare facilities.

The integration of AI into medical equipment design has also led to the development of personalized healthcare solutions. By analyzing patient data, AI-powered devices can provide tailored treatment plans and recommendations based on an individual’s unique medical history and needs. This has the potential to improve patient outcomes and reduce the risk of adverse reactions to treatments.

Moreover, AI has also opened up new possibilities for remote patient monitoring. With the use of wearable devices and sensors, AI can continuously monitor a patient’s vital signs and alert healthcare professionals in case of any abnormalities. This has proven to be especially useful during the current COVID-19 pandemic, where remote monitoring has helped reduce the risk of exposure for both patients and healthcare workers.

In conclusion, the integration of AI into medical equipment design has had a profound impact on the healthcare industry. From improving accuracy and functionality to enabling personalized and remote healthcare solutions, AI has revolutionized the way medical equipment is designed and used. As technology continues to advance, we can expect to see even more innovative and life-changing developments in the field of healthcare equipment design.

Innovative Materials and Their Role in Improving Durability and Performance of Healthcare Equipment

In the world of healthcare, equipment design plays a crucial role in ensuring the safety and well-being of patients. With advancements in technology and research, the healthcare industry has seen a significant shift towards the use of innovative materials in the design of medical equipment. These materials not only improve the durability and performance of healthcare equipment but also have the potential to revolutionize the way healthcare is delivered.

One of the most significant challenges in healthcare equipment design is finding materials that can withstand the harsh conditions of medical environments. Traditional materials such as stainless steel and plastic have been the go-to choices for medical equipment due to their durability and ease of cleaning. However, these materials have their limitations, and with the increasing demand for more advanced medical procedures, the need for innovative materials has become more pressing.

One such material that has gained popularity in recent years is carbon fiber. This lightweight and strong material has been used in various industries, including aerospace and automotive, but its potential in healthcare equipment design is now being explored. Carbon fiber is not only durable but also resistant to corrosion, making it an ideal choice for medical equipment that comes into contact with bodily fluids and chemicals. Its lightweight nature also makes it easier for healthcare professionals to maneuver and transport equipment, reducing the risk of injury.

Another innovative material that is making waves in healthcare equipment design is titanium. This metal has been used in the medical field for decades, primarily in orthopedic implants. However, with advancements in manufacturing techniques, titanium is now being used in the design of other medical equipment such as surgical instruments and dental implants. Titanium is known for its strength, biocompatibility, and resistance to corrosion, making it an excellent choice for medical equipment that needs to withstand frequent sterilization and harsh chemical exposure.

In addition to carbon fiber and titanium, there are other materials that are being researched and tested for their potential use in healthcare equipment design. One such material is graphene, a thin layer of carbon atoms that is known for its strength, flexibility, and conductivity. Researchers are exploring the use of graphene in medical sensors and diagnostic equipment, as well as in the development of artificial organs and prosthetics. Its unique properties make it a promising material for the future of healthcare.

The use of innovative materials in healthcare equipment design not only improves durability but also enhances performance. For instance, the use of ceramic materials in the design of medical implants has shown to promote bone growth and reduce the risk of infection. This has led to better outcomes for patients and a decrease in the need for revision surgeries. Similarly, the use of polymers in the design of medical devices has allowed for more precise and efficient drug delivery, improving patient outcomes and reducing the risk of adverse reactions.

Moreover, the use of innovative materials in healthcare equipment design has also led to advancements in technology. For example, the development of flexible and stretchable electronics has allowed for the creation of wearable medical devices that can monitor vital signs and track patient data in real-time. This has the potential to revolutionize the way healthcare is delivered, allowing for more personalized and efficient treatment plans.

In conclusion, the use of innovative materials in healthcare equipment design is transforming the industry and improving patient care. These materials not only improve durability and performance but also open up new possibilities for the development of advanced medical technologies. As research in this field continues to progress, we can expect to see even more groundbreaking materials being used in the design of healthcare equipment, leading to a brighter and healthier future for all.

The Role of User-Centered Design in Creating More User-Friendly and Accessible Medical Devices

In the world of healthcare, the design of medical equipment plays a crucial role in the delivery of quality patient care. From diagnostic tools to surgical instruments, the design of these devices can greatly impact their effectiveness and usability. As technology continues to advance, the demand for more user-friendly and accessible medical devices has become increasingly important. This is where user-centered design comes into play, revolutionizing the way healthcare equipment is designed and improving the overall patient experience.

User-centered design is a process that involves understanding the needs and preferences of the end-users, in this case, healthcare professionals and patients, and incorporating those insights into the design of medical devices. This approach puts the user at the center of the design process, ensuring that the final product meets their needs and is easy to use. By involving users in the design process, medical device manufacturers can create products that are more intuitive, efficient, and effective.

One of the key benefits of user-centered design in healthcare equipment is its ability to improve usability. Medical devices are often complex and require specialized training to operate. However, by involving end-users in the design process, manufacturers can create devices that are easier to use, reducing the need for extensive training. This is especially important in emergency situations where time is of the essence, and healthcare professionals need to be able to use the equipment quickly and efficiently.

Moreover, user-centered design also takes into consideration the physical and cognitive abilities of the end-users. For example, a medical device designed for use by elderly patients may have larger buttons and clearer instructions to accommodate for any vision or dexterity issues. By considering the needs of different user groups, medical devices can be designed to be more accessible and inclusive, ensuring that all patients receive the same level of care.

Another aspect of user-centered design in healthcare equipment is its focus on safety. Medical devices are used to diagnose and treat illnesses, and any errors or malfunctions can have serious consequences. By involving end-users in the design process, potential safety hazards can be identified and addressed before the device is put into use. This not only ensures the safety of patients but also protects healthcare professionals who use the equipment on a daily basis.

In addition to improving usability and safety, user-centered design also has the potential to enhance the overall patient experience. Medical procedures can be stressful and intimidating for patients, and the design of medical equipment can greatly impact their comfort and satisfaction. By involving patients in the design process, manufacturers can create devices that are less intimidating and more user-friendly, making the overall experience more positive for patients.

Furthermore, user-centered design also takes into consideration the workflow of healthcare professionals. By understanding their needs and preferences, medical devices can be designed to fit seamlessly into their daily routines, making their jobs easier and more efficient. This can lead to improved patient outcomes as healthcare professionals can focus more on providing quality care rather than struggling with complicated equipment.

In conclusion, user-centered design is revolutionizing the way healthcare equipment is designed, with a focus on improving usability, safety, and the overall patient experience. By involving end-users in the design process, medical device manufacturers can create products that are more intuitive, accessible, and efficient. As technology continues to advance, the role of user-centered design in healthcare equipment design will only become more crucial in delivering quality patient care.

Q&A

1. How is research revolutionizing healthcare equipment design?

Research is revolutionizing healthcare equipment design by providing valuable insights and data that can inform the development of new and improved medical devices. Through research, designers can better understand the needs and preferences of healthcare professionals and patients, as well as identify potential areas for improvement in existing equipment. This leads to the creation of more efficient, effective, and user-friendly healthcare equipment.

2. What role does technology play in this revolution?

Technology plays a crucial role in the revolution of healthcare equipment design. Advancements in technology have allowed for the development of more sophisticated and precise medical devices, such as imaging equipment and surgical tools. Additionally, technology has made it possible to collect and analyze large amounts of data, which can inform the design process and lead to more innovative and effective equipment.

3. How does research benefit patients in terms of healthcare equipment?

Research benefits patients in terms of healthcare equipment by ensuring that the devices they use are safe, effective, and tailored to their needs. Through research, designers can identify potential risks and address them before the equipment is released to the market. Additionally, research helps to improve the usability and functionality of healthcare equipment, making it easier for patients to receive the care they need.

4. What are some examples of how research has led to advancements in healthcare equipment design?

There are many examples of how research has led to advancements in healthcare equipment design. For instance, research on patient needs and preferences has led to the development of more comfortable and user-friendly medical devices, such as wearable technology for monitoring vital signs. Research on materials and manufacturing processes has also led to the creation of more durable and cost-effective equipment. Additionally, research on medical procedures and techniques has informed the design of specialized equipment, such as minimally invasive surgical tools.

Conclusion

In conclusion, research is playing a crucial role in revolutionizing healthcare equipment design. Through extensive studies and advancements in technology, researchers are able to develop innovative and efficient equipment that can greatly improve patient outcomes and overall healthcare delivery. From advanced imaging systems to personalized medical devices, research is continuously pushing the boundaries of what is possible in healthcare equipment design. This not only benefits patients, but also healthcare professionals who can now provide better and more precise care. With the ongoing advancements in research, we can expect to see even more groundbreaking developments in healthcare equipment design in the future.