Machinery & Equipment: Fueling Industrial Innovation Through Research

Machinery & Equipment: Driving Industrial Progress Through Research

Introduction:

In the industrial age, machinery and equipment have been the backbone of progress, propelling various industries forward through innovation and efficiency. From the steam engines of the 18th century to the advanced robotics and automation systems of today, continuous research and development in machinery and equipment have played a crucial role in shaping the modern world. This article delves into how research in this field drives industrial progress, exploring various aspects such as technological advancements, economic impacts, and future trends.

Technological Advancements in Machinery & Equipment

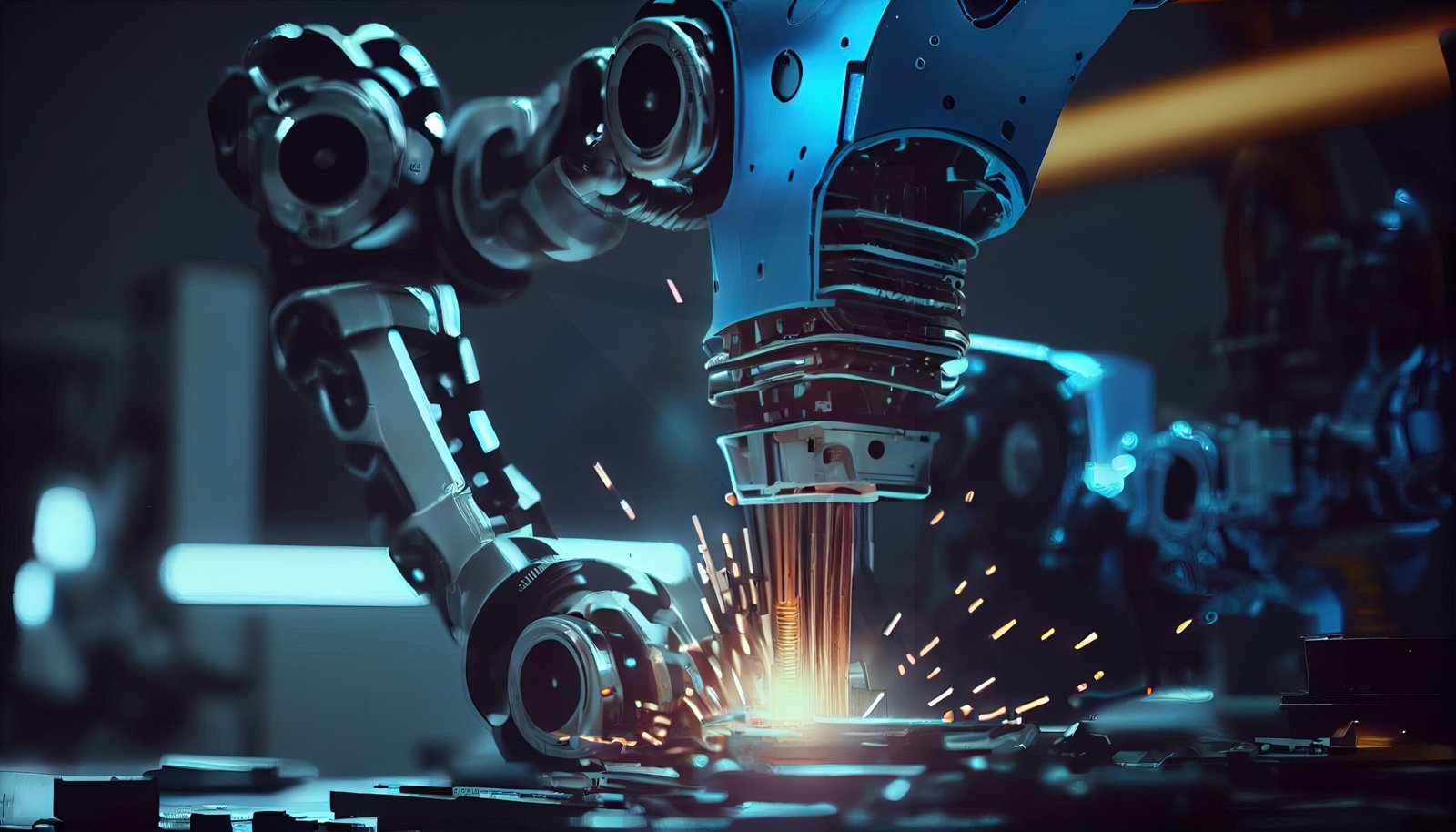

Technological advancements in machinery and equipment have revolutionized industries by increasing productivity, reducing manual labor, and enhancing precision. One of the most significant developments is the integration of automation and robotics. For instance, industrial robots are now widely used in manufacturing to perform repetitive tasks with high accuracy, reducing human error and increasing efficiency. According to the International Federation of Robotics, the global operational stock of industrial robots reached 2.7 million units in 2020[^1^].

Another major advancement is the advent of the Internet of Things (IoT) in industrial settings, often referred to as the Industrial Internet of Things (IIoT). IIoT connects machines and equipment to a network, enabling real-time data collection and analysis. This connectivity allows for predictive maintenance, reducing downtime and extending the lifespan of machinery. As per a report by McKinsey & Company, predictive maintenance could reduce maintenance costs by 20% and downtime by 50%[^2^].

Furthermore, advancements in materials science have led to the development of more durable and efficient machinery. Innovations such as lightweight composites and high-strength alloys have enabled the creation of equipment that is both robust and energy-efficient. These materials not only enhance the performance of machinery but also contribute to sustainability by reducing energy consumption and emissions.

[^1^]: International Federation of Robotics

[^2^]: McKinsey & Company

Economic Impacts of Machinery & Equipment Innovations

The economic impact of innovations in machinery and equipment is profound, driving growth and competitiveness in various industries. Firstly, improved machinery leads to increased productivity, allowing businesses to produce more goods at a lower cost. This efficiency translates into competitive pricing and higher profit margins. For example, a report by Deloitte highlights that automation in manufacturing can boost productivity by up to 40%^3^.

Additionally, advancements in machinery and equipment can lead to the creation of new markets and industries. For instance, the development of renewable energy technologies such as wind turbines and solar panels has given rise to a booming green energy sector. According to the International Renewable Energy Agency (IRENA), the renewable energy industry employed over 11 million people worldwide in 2018[^4^].

Moreover, investments in research and development (R&D) in machinery and equipment stimulate economic growth by creating high-paying jobs in engineering, manufacturing, and technology sectors. Governments and private enterprises that invest heavily in R&D tend to experience robust economic growth. The World Bank notes that countries investing over 3% of their GDP in R&D generally see higher levels of innovation and economic performance[^5^].

[^4^]: International Renewable Energy Agency

[^5^]: World Bank

Safety and Environmental Considerations

While advancements in machinery and equipment have numerous benefits, they also bring safety and environmental challenges. Ensuring the safety of workers operating complex machinery is paramount. Innovations such as machine learning and IoT have made it possible to implement advanced safety systems. For instance, sensors and real-time monitoring can detect potential hazards and shut down equipment automatically to prevent accidents. According to the Occupational Safety and Health Administration (OSHA), the integration of these technologies can reduce workplace injuries by 25%[^6^].

Environmental considerations are equally critical. Machinery and equipment can have significant environmental impacts, including energy consumption and emissions. However, research is paving the way for greener technologies. The development of energy-efficient machines and the integration of renewable energy sources in industrial processes are reducing the carbon footprint of manufacturing. The Environmental Protection Agency (EPA) reports that energy-efficient machinery can lower greenhouse gas emissions by up to 30%[^7^].

Another notable development is the recycling of industrial machinery. Circular economy principles are being applied to machinery production, where old equipment is refurbished or recycled, reducing waste and conserving resources. The Ellen MacArthur Foundation highlights that a circular approach can reduce material costs by 20% and lower environmental impact[^8^].

[^6^]: Occupational Safety and Health Administration

[^7^]: Environmental Protection Agency

[^8^]: Ellen MacArthur Foundation

Future Trends in Machinery & Equipment Research

Looking ahead, research in machinery and equipment is set to drive even more significant changes in the industrial landscape. One of the most promising trends is the development of smart factories. These facilities integrate advanced technologies such as AI, IoT, and big data analytics to optimize production processes. Smart factories can adapt in real-time, enhancing efficiency and reducing waste. According to a report by PwC, smart factories could boost manufacturing productivity by up to 25% by 2025^9^.

Another future trend is the advancement of additive manufacturing, commonly known as 3D printing. This technology allows for the creation of complex parts and equipment with high precision and minimal waste. The 3D printing market is expected to grow significantly, with markets and markets predicting it will reach $34.8 billion by 2024[^10^]. This growth is driven by the ability to produce custom machinery parts quickly and cost-effectively.

Lastly, sustainability will continue to be a major focus. Research is ongoing into developing machinery that uses alternative fuels and energy sources. Hydrogen fuel cells, for instance, are being explored as a potential power source for industrial machinery. The Hydrogen Council states that hydrogen-powered equipment could play a crucial role in achieving zero-emission industrial operations[^11^].

[^10^]: Markets and Markets

[^11^]: Hydrogen Council

Conclusion:

Research in machinery and equipment is a driving force behind industrial progress, fostering technological advancements, economic growth, and sustainability. The integration of automation, IoT, and advanced materials has transformed industries, while ongoing research promises even greater innovations in the future. As we move forward, the continued focus on safety, environmental impact, and economic benefits will ensure that machinery and equipment remain pivotal in the ongoing evolution of industrial processes.

Key Takeaways:

- Technological Advancements:

- Integration of automation and robotics.

- The rise of IIoT for real-time data and predictive maintenance.

- Innovations in materials science for durable, efficient machinery.

- Economic Impacts:

- Increased productivity and cost-efficiency.

- Creation of new markets and industries.

- High-paying jobs in R&D stimulating economic growth.

- Safety and Environmental Considerations:

- Advanced safety systems reducing workplace injuries.

- Energy-efficient and greener technologies reducing environmental impact.

- Recycling and circular economy principles in machinery production.

- Future Trends:

- Smart factories enhancing efficiency and reducing waste.

- Growth of 3D printing for custom, cost-effective machinery parts.

- Development of sustainable machinery using alternative fuels.

FAQs

1. What is the role of automation in industrial machinery?

- Automation reduces manual labor, enhances precision, and increases productivity.

- Industrial robots perform repetitive tasks with high accuracy.

- Automation can boost manufacturing productivity by up to 40%.

2. How does the Industrial Internet of Things (IIoT) benefit machinery?

- IIoT connects machines for real-time data collection and analysis.

- It enables predictive maintenance, reducing downtime and maintenance costs.

- Enhanced connectivity improves overall operational efficiency.

3. What are some key materials innovations in machinery and equipment?

- Development of lightweight composites and high-strength alloys.

- Use of durable, energy-efficient materials in machinery production.

- Materials innovations contribute to sustainability by reducing emissions.

4. How do machinery advancements impact the economy?

- Increased productivity leads to competitive pricing and higher profit margins.

- Innovations create new markets, such as renewable energy sectors.

- R&D investments stimulate economic growth and create high-paying jobs.

5. What are some safety technologies used in modern machinery?

- Integration of sensors and real-time monitoring systems.

- Automatic shutdown mechanisms to prevent accidents.

- Machine learning algorithms to predict and mitigate safety risks.

6. How does energy-efficient machinery benefit the environment?

- Reduces greenhouse gas emissions and energy consumption.

- Contributes to sustainable industrial processes.

- Can lower the carbon footprint of manufacturing by up to 30%.

7. What is additive manufacturing and its significance?

- Also known as 3D printing, it creates complex parts with high precision.

- Reduces material waste and production costs.

- Expected to grow significantly, revolutionizing custom machinery production.

8. What are smart factories and their potential impact?

- Facilities that integrate AI, IoT, and big data for optimized production.

- Can adapt in real-time, enhancing efficiency and reducing waste.

- Could boost manufacturing productivity by up to 25% by 2025.

9. How does recycling apply to industrial machinery?

- Refurbishing old equipment reduces waste and conserves resources.

- Circular economy principles minimize environmental impact.

- Recycling can lower material costs and improve sustainability.

10. What future trends are expected in machinery and equipment research?

- Continued development of smart factories and AI integration.

- Expansion of 3D printing technologies for industrial use.

- Focus on sustainable machinery using alternative fuels like hydrogen.

By understanding and embracing these advancements, industries can continue to thrive, innovate, and contribute to global progress in a sustainable and efficient manner.