Discover the latest research on sustainability in medical device manufacturing and its impact on the environment. Go green with your devices.

Sustainability in Medical Device Manufacturing Research

Table of Contents

- Introduction

- Sustainable Materials and Design in Medical Device Manufacturing

- Reducing Waste and Improving Efficiency in Medical Device Production

- The Role of Renewable Energy in Sustainable Medical Device Manufacturing

- Implementing Sustainable Practices in Supply Chain Management for Medical Devices

- Q&A

- Conclusion

“Building a healthier future, one sustainable device at a time.”

Introduction

Sustainability in medical device manufacturing research is a growing area of focus in the healthcare industry. With the increasing demand for medical devices and the impact of their production on the environment, there is a need for sustainable practices in the manufacturing process. This involves considering the entire life cycle of a medical device, from design and production to disposal, and finding ways to reduce its environmental impact. In recent years, there has been a push towards more sustainable and eco-friendly solutions in medical device manufacturing, and research in this field is crucial for the future of healthcare and the planet. In this introduction, we will explore the importance of sustainability in medical device manufacturing research and its potential benefits for both the industry and the environment.

Sustainable Materials and Design in Medical Device Manufacturing

Sustainability has become a crucial aspect in all industries, including medical device manufacturing. With the increasing global focus on environmental conservation and the need for sustainable practices, it is imperative for medical device manufacturers to incorporate sustainable materials and design in their production processes.

The use of sustainable materials in medical device manufacturing has gained significant attention in recent years. These materials are defined as those that have a minimal impact on the environment and can be replenished or recycled. They are also known as green materials and are sourced from renewable resources such as plants, animals, and minerals.

One of the main benefits of using sustainable materials in medical device manufacturing is the reduction of carbon footprint. Traditional materials, such as plastics, have a significant impact on the environment due to their non-biodegradable nature. On the other hand, sustainable materials, such as bioplastics, are biodegradable and do not contribute to the accumulation of waste in landfills. This not only reduces the carbon footprint but also helps in the conservation of natural resources.

Moreover, sustainable materials also have a lower energy requirement during the production process. This is because they are sourced from renewable resources and do not require extensive processing. For instance, traditional plastics are derived from petroleum, which involves energy-intensive processes such as drilling, refining, and transportation. In contrast, bioplastics are derived from plant-based sources, which require less energy and have a lower carbon footprint.

In addition to the use of sustainable materials, the design of medical devices also plays a crucial role in promoting sustainability. Design for sustainability (DfS) is a concept that focuses on creating products that have a minimal impact on the environment throughout their life cycle. This includes the design, production, use, and disposal stages.

One of the key principles of DfS is the use of eco-design techniques. These techniques involve the consideration of environmental factors during the design process, such as the choice of materials, energy efficiency, and end-of-life disposal. By incorporating eco-design techniques, medical device manufacturers can reduce the environmental impact of their products and promote sustainability.

Another aspect of sustainable design in medical device manufacturing is the concept of circular economy. This is a regenerative approach to production that aims to minimize waste and maximize the use of resources. In the context of medical device manufacturing, this can be achieved through the implementation of closed-loop systems, where materials are reused or recycled at the end of their life cycle.

The use of sustainable materials and design in medical device manufacturing also has economic benefits. With the increasing demand for sustainable products, manufacturers who incorporate these practices can gain a competitive advantage in the market. This is because consumers are becoming more environmentally conscious and are willing to pay a premium for sustainable products.

Furthermore, the use of sustainable materials and design can also lead to cost savings for manufacturers. This is due to the reduced energy and resource requirements, as well as the potential for reusing or recycling materials. In the long run, this can result in significant cost savings for manufacturers, making sustainability a financially viable option.

In conclusion, the incorporation of sustainable materials and design in medical device manufacturing is crucial for promoting environmental conservation and achieving economic benefits. By using sustainable materials, manufacturers can reduce their carbon footprint and energy requirements, while sustainable design practices can minimize waste and promote resource efficiency. As the demand for sustainable products continues to grow, it is essential for medical device manufacturers to embrace these practices and contribute to a more sustainable future.

Reducing Waste and Improving Efficiency in Medical Device Production

Sustainability has become a crucial aspect in all industries, including medical device manufacturing. With the increasing global focus on environmental conservation and resource management, it is imperative for medical device manufacturers to adopt sustainable practices in their production processes. This not only benefits the environment but also has a positive impact on the overall efficiency and cost-effectiveness of the manufacturing process.

One of the key areas where sustainability can be implemented in medical device manufacturing is in reducing waste. The production of medical devices often involves the use of various materials, such as plastics, metals, and electronics. These materials can generate a significant amount of waste during the manufacturing process, which can have a detrimental impact on the environment if not managed properly.

To address this issue, medical device manufacturers are now implementing waste reduction strategies in their production processes. This includes using recyclable materials, optimizing material usage, and implementing waste management systems. By using recyclable materials, manufacturers can reduce the amount of waste generated during the production process. This not only benefits the environment but also reduces the cost of raw materials, making the manufacturing process more cost-effective.

Optimizing material usage is another effective way to reduce waste in medical device manufacturing. This involves carefully planning and designing the production process to minimize material wastage. For example, manufacturers can use computer-aided design (CAD) software to design products with minimal material usage, reducing the amount of waste generated. Additionally, implementing lean manufacturing principles can also help in reducing waste by eliminating unnecessary steps and processes in the production process.

Apart from waste reduction, sustainability in medical device manufacturing also involves improving efficiency. This can be achieved by implementing energy-efficient practices in the production process. For instance, manufacturers can use energy-efficient equipment and machinery, such as LED lighting and energy-efficient motors, to reduce energy consumption. This not only reduces the carbon footprint of the manufacturing process but also leads to cost savings for the manufacturer.

Another aspect of improving efficiency in medical device manufacturing is streamlining the supply chain. This involves working closely with suppliers to ensure timely delivery of materials and components, reducing the need for excess inventory. By streamlining the supply chain, manufacturers can reduce the amount of waste generated from excess inventory and also improve the overall efficiency of the production process.

In addition to waste reduction and efficiency improvement, sustainability in medical device manufacturing also involves responsible disposal of waste. This includes proper disposal of hazardous materials and recycling of materials whenever possible. Manufacturers can work with specialized waste management companies to ensure that hazardous materials are disposed of safely and in compliance with environmental regulations. Recycling of materials, such as plastics and metals, not only reduces waste but also conserves natural resources.

Moreover, sustainability in medical device manufacturing also extends to the end-of-life stage of the product. Manufacturers can design products with a focus on recyclability and ease of disassembly. This allows for the recovery of valuable materials from the product, reducing the need for raw materials in the production of new devices.

In conclusion, sustainability in medical device manufacturing is crucial for the environment, as well as for the efficiency and cost-effectiveness of the production process. By implementing waste reduction strategies, improving efficiency, and responsible disposal of waste, manufacturers can contribute to a more sustainable future while also benefiting their bottom line. It is essential for all stakeholders in the medical device industry to work together towards a more sustainable approach to manufacturing, ensuring a healthier planet for future generations.

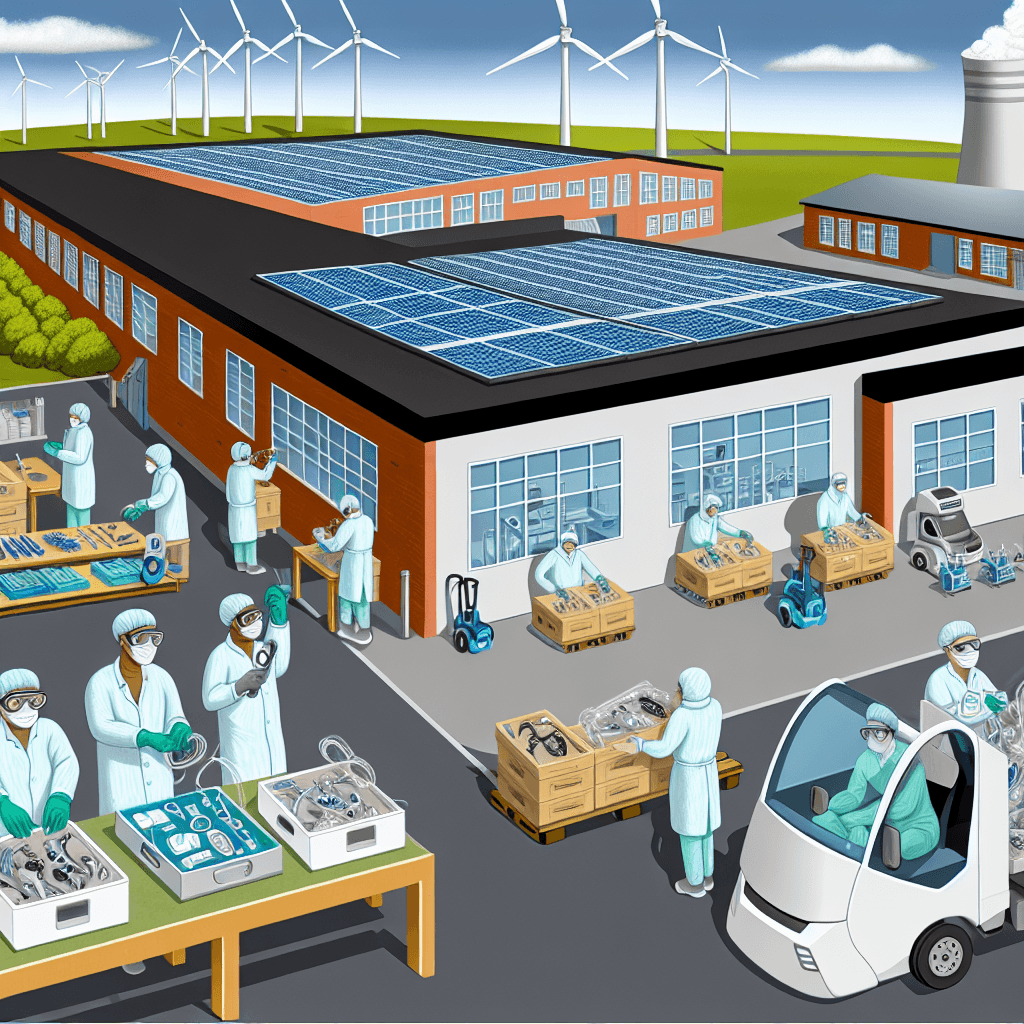

The Role of Renewable Energy in Sustainable Medical Device Manufacturing

Sustainability has become a crucial aspect in all industries, including medical device manufacturing. With the increasing global focus on environmental conservation and reducing carbon footprint, it is imperative for medical device manufacturers to adopt sustainable practices in their production processes. One of the key components of sustainability in this industry is the use of renewable energy sources.

Renewable energy refers to energy that is generated from natural resources such as sunlight, wind, water, and geothermal heat. Unlike fossil fuels, which are finite resources, renewable energy sources are constantly replenished and have a significantly lower impact on the environment. In recent years, there has been a growing trend towards the use of renewable energy in medical device manufacturing research, and for good reason.

Firstly, the use of renewable energy sources in medical device manufacturing reduces the carbon footprint of the industry. The production of medical devices requires a significant amount of energy, and the majority of this energy comes from non-renewable sources such as coal and natural gas. These sources emit large amounts of greenhouse gases, contributing to climate change and environmental degradation. By switching to renewable energy sources, medical device manufacturers can significantly reduce their carbon emissions and contribute to a cleaner and healthier environment.

Moreover, renewable energy sources are also cost-effective in the long run. While the initial investment in renewable energy infrastructure may be higher, the operational costs are significantly lower compared to traditional energy sources. This is because renewable energy sources do not require fuel, and the maintenance costs are minimal. As a result, medical device manufacturers can save on energy costs, which can then be reinvested in research and development, leading to innovation and improved products.

In addition to reducing carbon emissions and cost savings, the use of renewable energy sources also has a positive impact on the reputation of medical device manufacturers. In today’s society, consumers are becoming increasingly conscious of the environmental impact of the products they purchase. By using renewable energy sources, medical device manufacturers can demonstrate their commitment to sustainability and attract environmentally conscious consumers. This can also lead to increased brand loyalty and a competitive advantage in the market.

Furthermore, the use of renewable energy sources in medical device manufacturing can also have a positive impact on the health and safety of workers. Traditional energy sources such as coal and natural gas can release harmful pollutants into the air, which can have adverse effects on the health of workers. By switching to renewable energy sources, medical device manufacturers can create a safer and healthier working environment for their employees.

One of the most significant challenges in the adoption of renewable energy sources in medical device manufacturing is the initial investment required. However, governments and organizations around the world are providing incentives and subsidies to encourage the use of renewable energy sources. For instance, the US government offers tax credits for companies that invest in renewable energy infrastructure. This can help offset the initial costs and make it more feasible for medical device manufacturers to switch to renewable energy sources.

In conclusion, the use of renewable energy sources in medical device manufacturing research plays a crucial role in promoting sustainability in the industry. It not only reduces carbon emissions and operational costs but also has a positive impact on the reputation of medical device manufacturers and the health and safety of workers. With the increasing availability of incentives and subsidies, it is becoming more feasible for companies to make the switch to renewable energy sources. As the industry continues to evolve, it is essential for medical device manufacturers to prioritize sustainability and embrace renewable energy sources in their production processes.

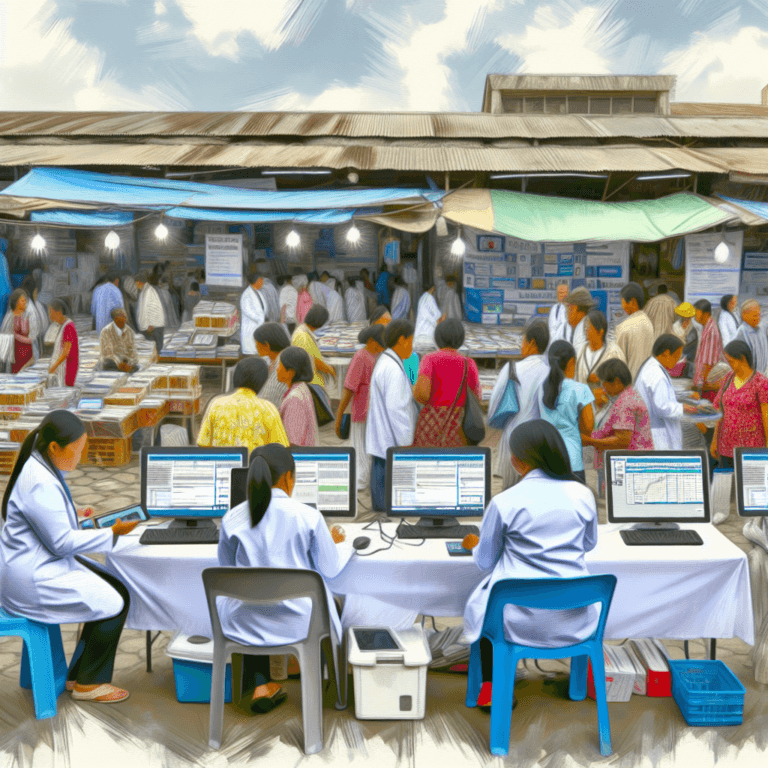

Implementing Sustainable Practices in Supply Chain Management for Medical Devices

Sustainability has become a crucial aspect in all industries, including the medical device manufacturing sector. With the increasing global focus on environmental conservation and social responsibility, companies are now expected to incorporate sustainable practices into their operations. This includes the supply chain management process, which plays a significant role in the overall sustainability of a company.

The supply chain management process involves the movement of raw materials, components, and finished products from suppliers to manufacturers, distributors, and ultimately to the end-users. This process has a significant impact on the environment, as it consumes energy, generates waste, and emits greenhouse gases. Therefore, implementing sustainable practices in supply chain management is essential for reducing the environmental footprint of medical device manufacturing.

One of the key ways to implement sustainable practices in supply chain management for medical devices is by reducing the carbon footprint. This can be achieved by optimizing transportation routes, using alternative modes of transportation such as rail or sea, and implementing green logistics practices. By reducing the distance traveled and using more environmentally friendly modes of transportation, companies can significantly reduce their carbon emissions.

Another crucial aspect of sustainable supply chain management is responsible sourcing. This involves ensuring that the raw materials and components used in the manufacturing process are ethically and sustainably sourced. This includes considering factors such as fair labor practices, environmental impact, and social responsibility when selecting suppliers. By working with responsible suppliers, companies can ensure that their supply chain is not contributing to any unethical or unsustainable practices.

In addition to responsible sourcing, companies can also implement sustainable packaging practices in their supply chain management. This includes using recyclable or biodegradable materials for packaging and reducing the amount of packaging used. By doing so, companies can reduce the amount of waste generated and contribute to a more circular economy.

Furthermore, implementing sustainable practices in supply chain management can also have financial benefits for companies. By optimizing transportation routes and reducing waste, companies can save on transportation and disposal costs. Additionally, by working with responsible suppliers, companies can avoid any potential legal or reputational risks associated with unethical or unsustainable practices.

However, implementing sustainable practices in supply chain management for medical devices is not without its challenges. One of the main challenges is the lack of transparency in the supply chain. Many companies have complex and global supply chains, making it difficult to track the origin and sustainability of all components and materials used. To overcome this challenge, companies can use technology such as blockchain to create a transparent and traceable supply chain.

Another challenge is the initial cost of implementing sustainable practices. While there may be long-term financial benefits, the initial investment in sustainable transportation, packaging, and sourcing practices can be significant. To overcome this challenge, companies can start by implementing small changes and gradually scaling up their sustainable practices.

In conclusion, implementing sustainable practices in supply chain management for medical devices is crucial for reducing the environmental impact of the industry. By reducing the carbon footprint, responsible sourcing, and implementing sustainable packaging practices, companies can contribute to a more sustainable future. While there may be challenges in implementing these practices, the long-term benefits for both the environment and the company make it a worthwhile endeavor. As the demand for sustainable products continues to grow, it is essential for medical device manufacturers to prioritize sustainability in their supply chain management processes.

Q&A

1. What are some sustainable practices in medical device manufacturing research?

Some sustainable practices in medical device manufacturing research include using eco-friendly materials, reducing waste and energy consumption, implementing recycling programs, and promoting sustainable supply chain management.

2. How can medical device manufacturers reduce their carbon footprint?

Medical device manufacturers can reduce their carbon footprint by using renewable energy sources, optimizing transportation and logistics, implementing energy-efficient processes, and promoting sustainable product design.

3. What role does sustainability play in the development of new medical devices?

Sustainability plays a crucial role in the development of new medical devices as it ensures that the devices are environmentally friendly, socially responsible, and economically viable. It also helps to meet regulatory requirements and improve the overall quality of the product.

4. What are the benefits of incorporating sustainability into medical device manufacturing research?

Incorporating sustainability into medical device manufacturing research can lead to reduced costs, improved efficiency, enhanced brand reputation, and increased customer satisfaction. It also helps to minimize environmental impact and promote a healthier and more sustainable future.

Conclusion

In conclusion, sustainability in medical device manufacturing research is crucial for the future of healthcare. It involves implementing environmentally friendly practices, reducing waste and emissions, and promoting ethical and socially responsible production. By prioritizing sustainability, medical device manufacturers can not only contribute to a healthier planet, but also improve the quality and safety of their products. It is important for the industry to continue investing in sustainable research and development to ensure a sustainable and ethical future for healthcare.